How does a safety relay work? Relays with Forcibly guided contacts

Safety relays are essential devices that monitor for potential errors or faults in machinery or plants. In this article, we will take a look in more detail about safety relays, how they work and the differences they can make within electrical applications to improve safety to both the workforce and equipment.

How does a safety relay work?

Safety relays ensure operation of equipment can only occur when the safety requirements have been fulfilled. A modern safety relay integrates signal and control inputs, control outputs and outputs that allow correct operation to be monitored. For example, contacts may be welded, and this detection is used to prevent the commencement of operation). Applications that might require the use of a safety relay include:

- Guards

- Light Curtains

- Safety Mats

- 2-Hand Control

When an error occurs, the safety relay will initiate a safe and reliable response. Each safety relay monitors a specific function. They are a simple and efficient way to meet existing safety standards, resulting in safe operation for your workforce and equipment as well as ensuring their long life. Reducing risks should be a number one priority for all organisations, to protect the welfare of their employees and to reduce expensive damages to equipment. With Finder’s range of modular relays with forcibly guided contacts, we can ensure protection.

What is the difference between safety relay and normal relay?

A modern safety relay described above is a complex assembly of logic elements (possibly even a microcontroller) as well as switching elements. So, it is not in itself a simple relay.

However, at the heart of many safety relays or systems will be a relay with forcibly guided contacts. The forcibly guided contact relay has normally open and normally closed contacts mechanically linked in such a way that they cannot both be closed at the same time. This allows fault conditions such as welded contacts to be determined.

Finder has several safety offerings for different applications, which will be discussed further on in the article.

How do relays improve safety?

The main way relays provide safety is by providing isolation. Finder’s industrial relays provide the equivalent of double insulation between the coil and the contacts.

Relays with dedicated safety features (50 Series, 7S Series and the 22 Series with mirror contacts or mechanically linked auxiliary contacts) can be incorporated in ways that allow the correct operation to be monitored and incorrect operation detected. Note the detailed design of a safety system to provide the appropriate level of protection is a complex subject.

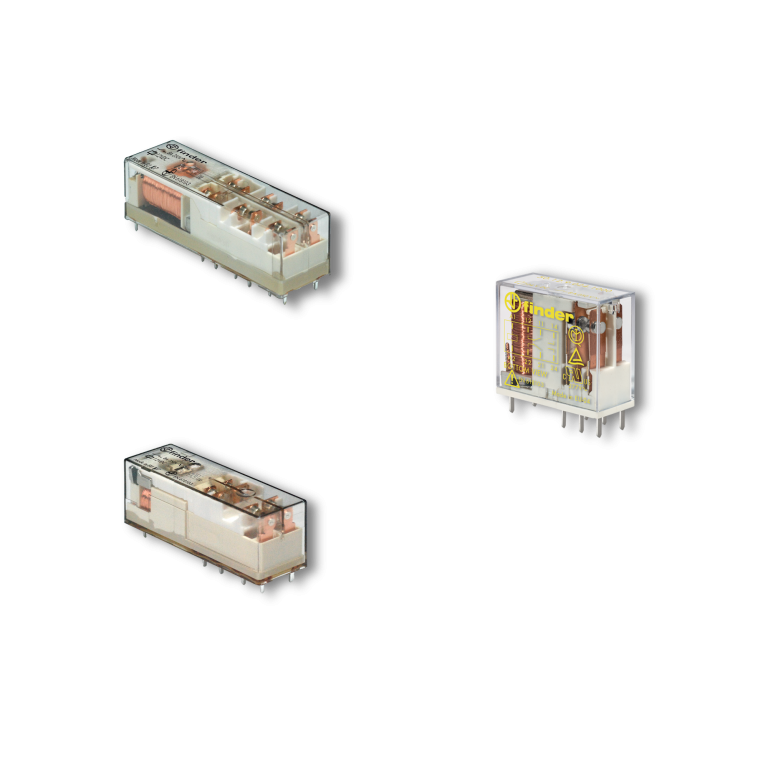

Finder’s range of safety relays with forcibly guided contacts

FINDER 7S SERIES

Finder 7S Series are relays with forcibly guided contacts designed for DIN rail mounting. These would normally be used with a safety PLC to provide the monitoring and logic.

The 7S Series consists of relays with forcibly guided contacts for SIL 2/SIL 3 safety applications.

The features include (according to Type):

- For safety applications, with class A forcibly guided contact relays (EN 50205)

- 2 pole (1NO + 1 NC), 4 pole (2 NO + 2 NC and 3 NO + 1 NC) or 6 pole (4 NO + 2 NC)

- 35 mm rail (EN 60715) mount, 22.5 mm wide

- Available version for railway applications

Safety expansion modules with class A forcibly guided contact relays EN 61810-3 (previously EN 50205) for safety applications up to SIL 3. SIL 3 evaluated according to SIL EN 6508, for use in functional safety applications according to EN 62061 up to SIL 3 according to IEC 12849-1 up to PL e.

What is SIL?

SIL stands for Safety Integrity Level. A SIL is a measure of safety system performance, in terms of probability of failure on demand (PFD). There are four discrete integrity levels associated with SIL: SIL 1, SIL 2, SIL 3, and SIL 4. The higher the SIL level, the higher the associated safety level, and the lower probability that a system will fail to perform properly. As the SIL level increases, typically the installation and maintenance costs and complexity of the system also increase. Specifically for the process industries, SIL 4 systems are so complex and costly that they are not economically beneficial to implement.

FINDER 50 SERIES

Finder’s 50 Series are relays with forcibly guided contacts designed for PCB mounting. The 50 series could be incorporated into a safety relay or used to create a custom-designed PCB based safety system.

The 50 Series comprises relays that include the following features (according to Type):

- 2 Pole changeover contacts

- PCB Relay with forcibly guided contacts according to EN 50205 type B

- High physical separation between adjacent contacts

- 8 mm, 6 kV (1.2/50 μs) isolation, coil-contacts

- Flux proof: RT II

FINDER 22 SERIES

In the 22 Series for safety applications, Finder has modular contactors from 40 A and 63 A, with mirror contacts (Compliant with EN 60947-4-1: Mirror Contacts) and auxiliary modules according to EN 60947-5-1: Mechanically linked contacts. They are also:

✔ A key component in the construction of control systems required to meet safety directives

✔ Can be used in safety applications in combination with safety modules or expansions (Series 7S)

✔ Application examples: vehicle recharging columns, three-phase motor control or switching of other power loads in safety systems