Energy monitoring with OPTA and smart energy meters in Industry 5.0

TFA – Technologies For Automation is an Italian systems integrator active in the field of robotics, with a focus on energy efficiency and sustainability in industrial settings.

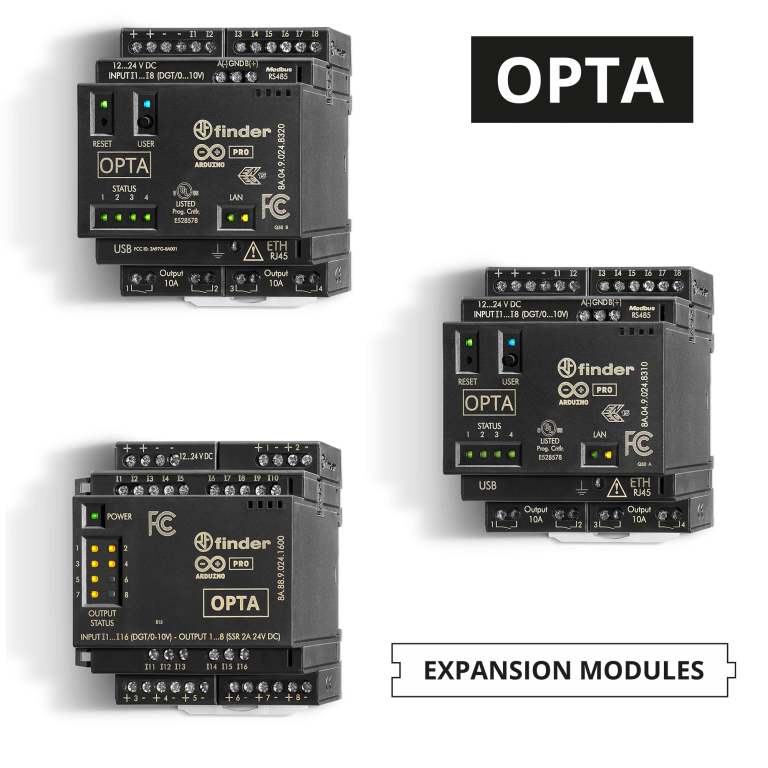

SERIES 8A | 7M

TFA – Technologies For Automation is an Italian systems integrator active in the field of robotics, with a focus on energy efficiency and sustainability in industrial settings. Using Finder’s 8A Series OPTA programmable logic relays and Type 7M.38 smart energy meters, it has been able to optimize energy consumption in industrial production lines, including those that use robots.

One of TFA’s suppliers – a company specializing in the production and marketing of industrial robots – had the need to certify the energy consumption of a new robot in order to certify energy-saving compliance with the Italian Transition 5.0 plan.

To meet this need for energy management optimization, an advanced solution based on the ELL-IoT system was implemented. This solution leverages the multi-protocol ELL-IoT gateway and dedicated web dashboards on a DEA (Digital Energy Analyzer) for energy monitoring for energy data certification for Industry 5.0. This was made possible by using a MID-certified Finder Type 7M.38.8.400.0212 energy meter, chosen for its accuracy and regulatory compliance.

This device collects consumption data and transmits them to a Finder OPTA programmable logic relay via Modbus RTU/RS485. OPTA, with its Ethernet and Wi-Fi connectivity capabilities, receives the data and sends it via MQTT to the ELL-IoT system. The latter processes the information, stores it in a database, and makes it accessible to the user through special intuitive web interface pages provided by DEA dashboards, where it is possible to view real-time electrical parameters, analyze historical energy consumption with custom filters, and use interactive graphs and tables for immediate data display.

The result obtained through collaboration with a Finder OPTA System Integrator Partner led to the adoption of the ELL-IoT-based solution. Indeed, the continuous monitoring of energy consumption and parameters enabled improved efficiency and reduced waste. Detailed analysis of historical and real-time data provided valuable support for operational decision making, and the DEA’s intuitive and interactive tools facilitated monitoring, and the elimination of anomalies. Today, constantly updated energy-consumption estimates enable more informed energy management. The synergy between these tools, the 7M Series energy meters and the Finder 8A Series OPTA programmable logic relays have enabled the implementation of an effective and technologically-advanced solution for energy monitoring in Industry 5.0.